Whats New

Material Selection & Design

AM Processing

Inspection & Testing

Consultation & Training

Research & Development

Enquiry Now

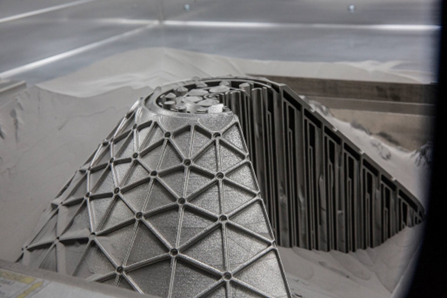

We have done this as one single part through additive printing, eliminating all bolts and nuts and this will have a higher level of tolerance,” he says. This technology is also very useful in auto and health industries, apart from defence. “We have a lot of auto companies in and around Chennai; if they need a complex design we can work with them or their MSME suppliers to convert it into a useful product,” he explains.

GE centre is equipped for mass production of any parts through additive manufacturing, which essentially creates parts layer by layer. “This a state-of-art 3D printing facility for metal printing, starting from design to printing and post-processing, to inspection, we are self-dependent. Most critical processes are in-house. Somebody comes to us with a part made by traditional manufacturing, we can analyse it, convert from traditional to additive manufacturing, and produce it here,”

MD - TAMCOE

-

Professionals Engaged

Smart and Hard Workers10+

-

Service Offered

We Provides All Industry Services10+

-

Privilege Partners

Most Trusted Company By Experts3+